Ahhh, ok. Can i have a 7D body, 21 mp 5dm2 cmos, 98% vf, no movie, the 51 pt multi cam 3500 fx af module, 5 fps with upgrade to 8 fps if mount bg, dual cf slots, auto ca correction in camera, dual axis electronic level in vf and lv and gridlines on demand? Oh yea, mind throwing in the speedlite wireless commander for free as well?

"Indecent Proposal" to camera makers

- Thread starter nightpiper

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Sion

Senior Member

Ahhh, ok. Can i have a 7D body, 21 mp 5dm2 cmos, 98% vf, no movie, the 51 pt multi cam 3500 fx af module, 5 fps with upgrade to 8 fps if mount bg, dual cf slots, auto ca correction in camera, dual axis electronic level in vf and lv and gridlines on demand? Oh yea, mind throwing in the speedlite wireless commander for free as well?

Do you also want the camera body vibrating or not? :bsmilie:

Nothing new.

Old hat already.

Leica can do for you. Pay.

Really?! Leica can do that if you pay? That's so cool!!!

On the other hand, it would seem like a modular camera is not too impossible... but it would become big. I'm thinking about the Hasselblad 500C/M type of modular cameras... haha! It's as customized as you can get at that time right?

And no, I didn't take econs or engineering. I do dream though... ;p

Really?! Leica can do that if you pay? That's so cool!!!

On the other hand, it would seem like a modular camera is not too impossible... but it would become big. I'm thinking about the Hasselblad 500C/M type of modular cameras... haha! It's as customized as you can get at that time right?

And no, I didn't take econs or engineering. I do dream though... ;p

The new Ricohs are more modular. But you swap out the whole sensor and lens array as a single block.

After going thru all replies, i do understand the argument here. But i like to reiterate the customisation is dictated by the makers themselves, not like u can change anything u like type. Very much like buying a desktop or laptop, u can't buy a imac & say u want to choose an Asus mainboard, use NEC firewire chip instead of TI, use Analog Devices audio chip instead of Realtek or Sigmatel, change the LCD display to a AMOLED type, etc.

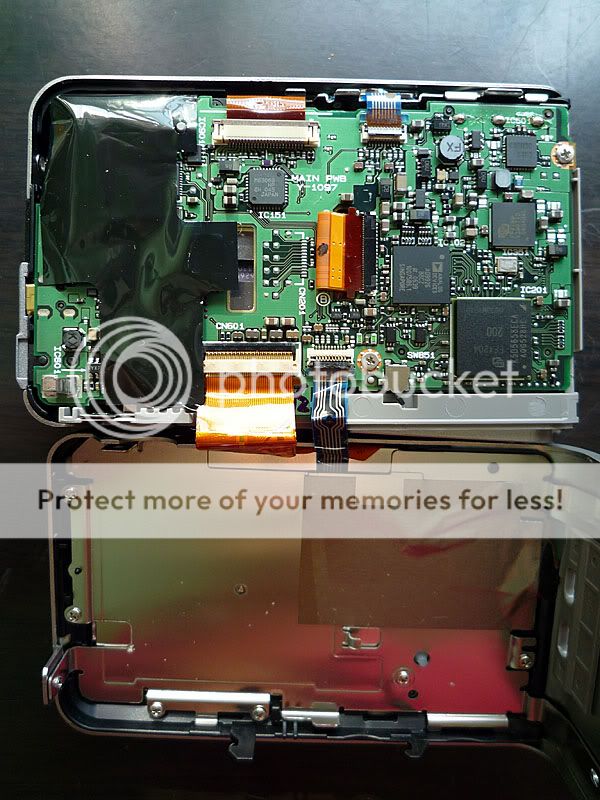

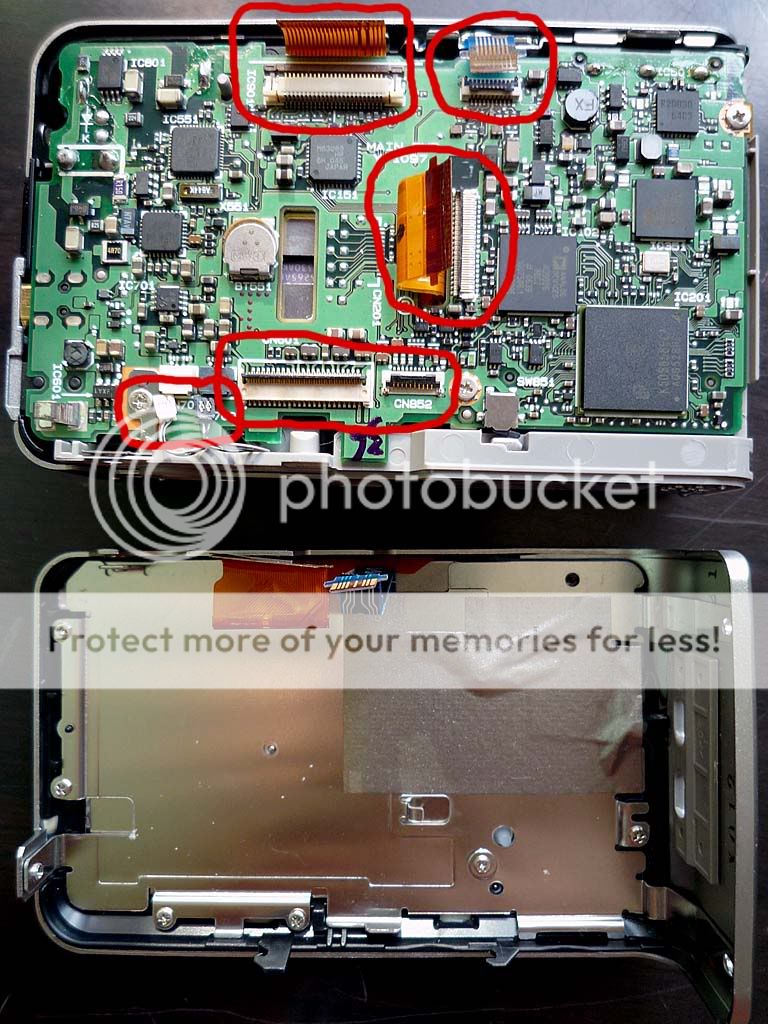

To bring this concept further, i did a little "digging". Took a spoilt P&S (Fuji F31) & opened it up to see what is inside:

As u can see there are connectors inside such a small P&S camera

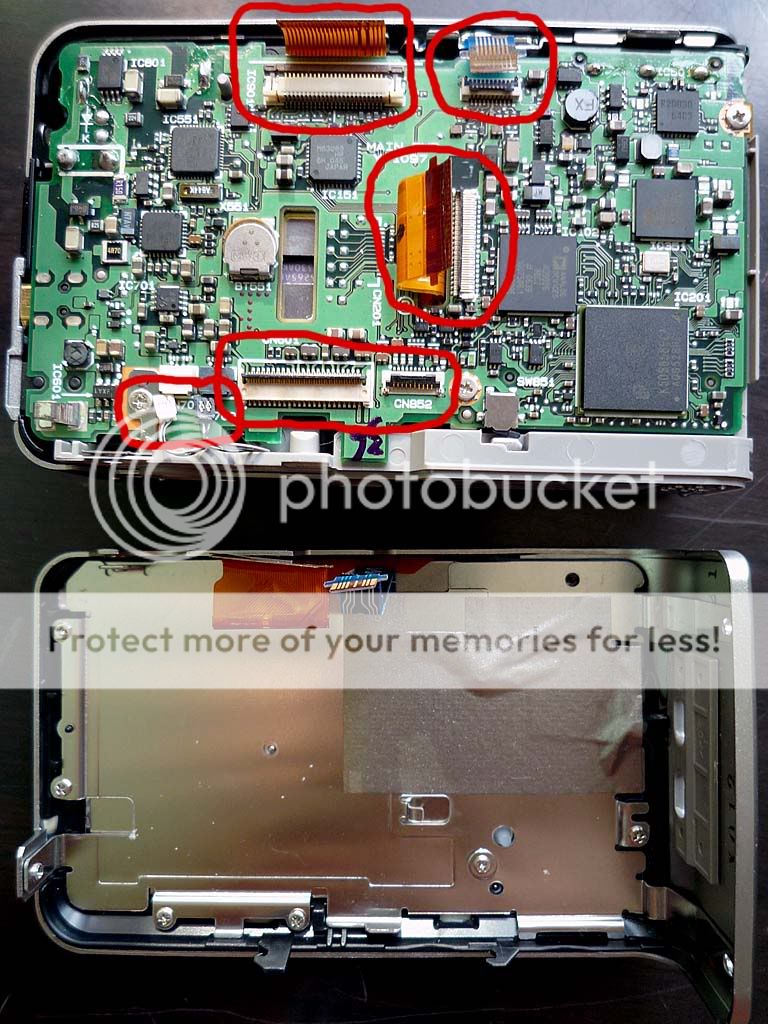

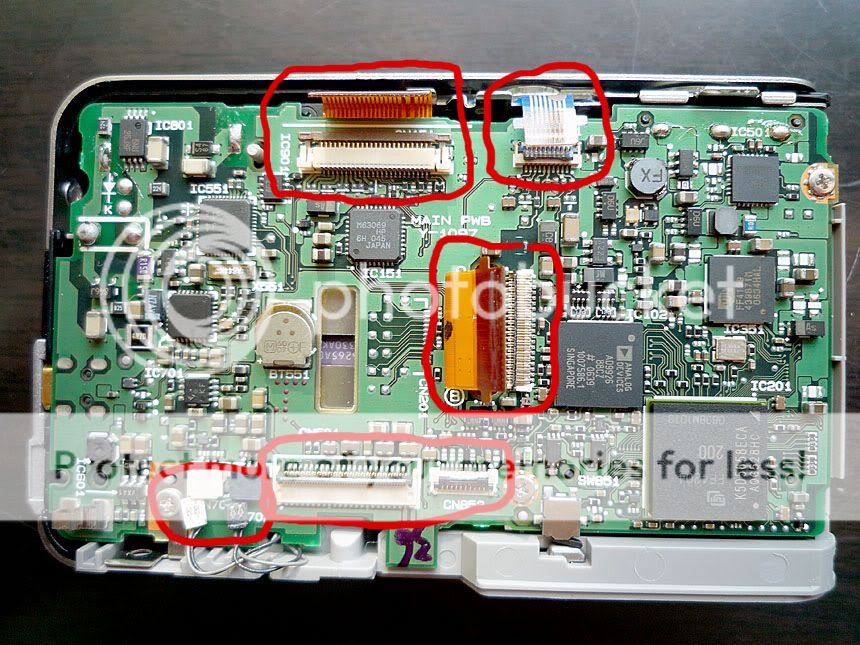

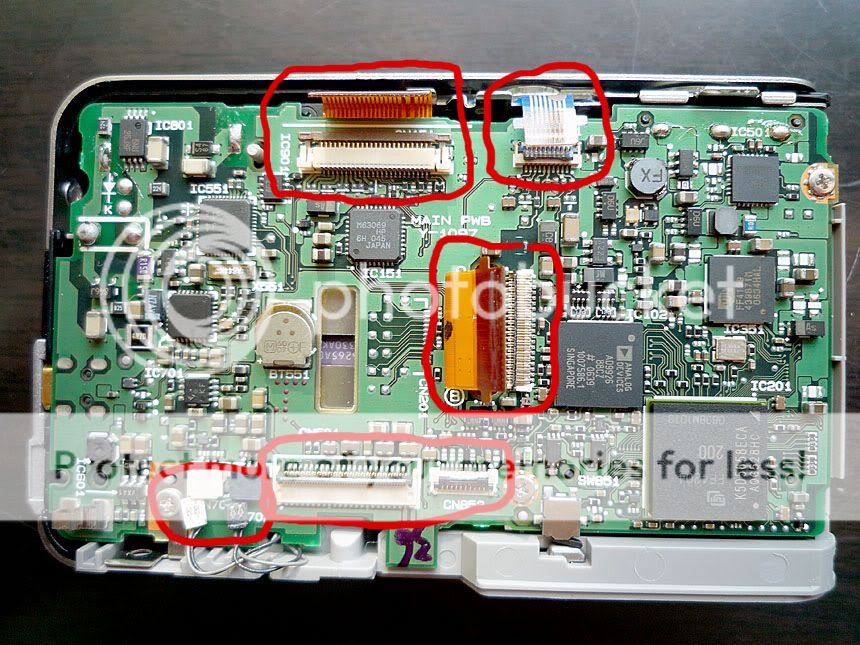

A little closer look

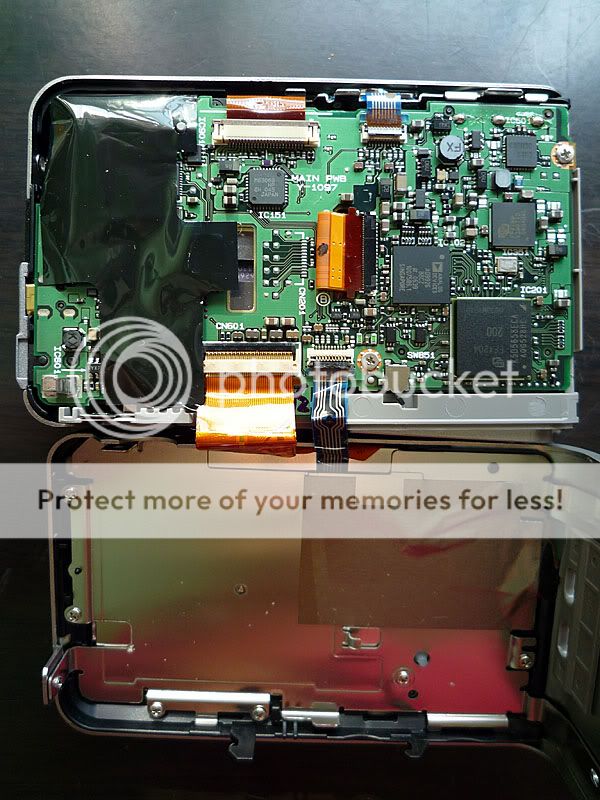

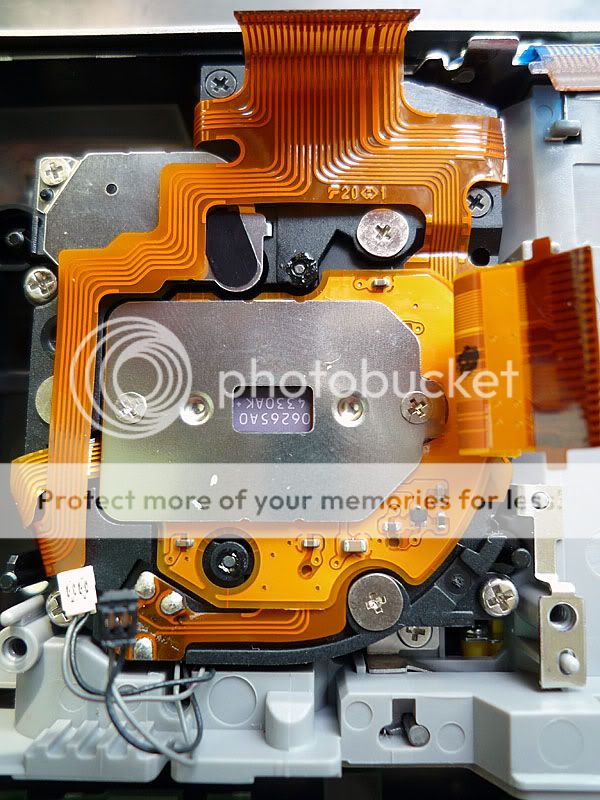

Further opening it reveals the lens assembly & the sensor portion

To bring this concept further, i did a little "digging". Took a spoilt P&S (Fuji F31) & opened it up to see what is inside:

As u can see there are connectors inside such a small P&S camera

A little closer look

Further opening it reveals the lens assembly & the sensor portion

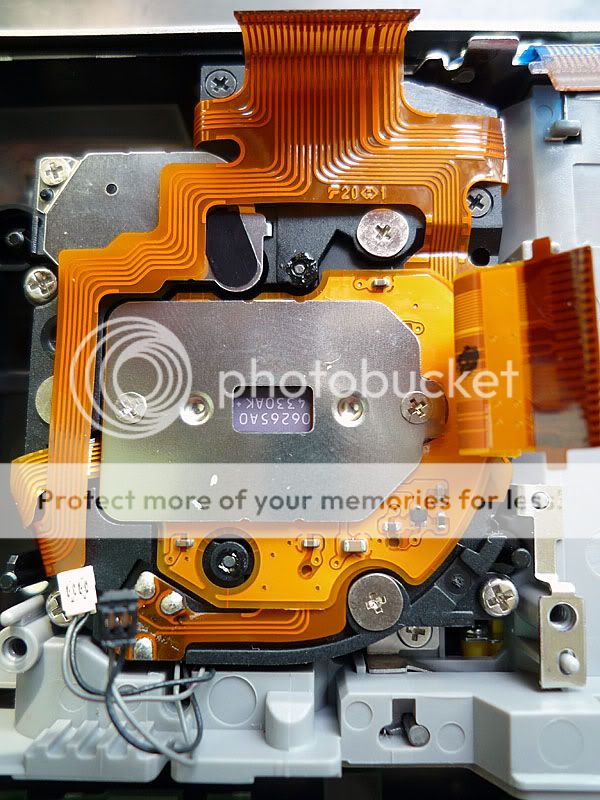

Closer look at the lens & sensor assembly

How the front looks like

The whole package

As much as how anyone wud like to think its all soldered & integrated tightly, the tiny P&S has connectors to join up all the modules together. Its done in modular way for easier trouble shooting & servicing. I've read from blogs & forums of how users open up their DSLR to mod the sensor to shoot IR, the disassembling also reveals similar method, ie, connectors joining modules together. Juz do a search for them & see for urself. So what is stopping makers from giving options to users to change some of the things at a premium?

Lets look at another argument here. If the config is more exp than another model or another brand of similar feature, whats the point? Lets say a Sony NEX5 is able to have some sort of customisation, the price ends up to $1500 from $1100. Whats stopping anyone from getting a DSLR, say a A230? For that price u can buy a DSLR, but that DSLR wud not have the advantage of small size & portability like the NEX5. So there's definitely a market for it & its not niche.

If u r using Sony DSLR & has invested lots of lenses & accessories, wud u get a Nikon D5000 or Canon 550D DSLR sys juz becos its cheaper than a customised NEX5 at $1500? It makes more sense to stick with a NEX5 thats customised to take advantage of the accessories & also lenses. In the DSLR territory its the same, wud u want to get another brand juz becos this brand has a cheaper model than the brand u r using? Jump ship, yes, but not for people who wants to continue using their arsenal built over the years.

Clean room assembling of cameras. That might be true for factory. My question to everyone out there is: Have u been inside the service center of any brand? Is it a clean room environment when they service equipment? I have been to a few in S'pore, can't say the same for the rest in the world. They r not clean room environment, juz aircon & people r not wearing any space suit, & that doesn't spell doom for the equipment & lenses being serviced there.

If the argument is made with a far fetch argument of "Who wants to customise a cam that cost $10k when the base model is $1k?" well, 1st of all, the makers controls what u can customised so it wudn't be over the hill. 2nd, if anyone wants to pay $5k juz to skin LV all over their NEX5 from LV boutique, thats their decision not mine or yours.

And yes, i do know how a DSLR works, & if u r not from research dept experimenting & developing new DSLR, i guess coming from u that the customising innards being impossible is moot.

How the front looks like

The whole package

As much as how anyone wud like to think its all soldered & integrated tightly, the tiny P&S has connectors to join up all the modules together. Its done in modular way for easier trouble shooting & servicing. I've read from blogs & forums of how users open up their DSLR to mod the sensor to shoot IR, the disassembling also reveals similar method, ie, connectors joining modules together. Juz do a search for them & see for urself. So what is stopping makers from giving options to users to change some of the things at a premium?

Lets look at another argument here. If the config is more exp than another model or another brand of similar feature, whats the point? Lets say a Sony NEX5 is able to have some sort of customisation, the price ends up to $1500 from $1100. Whats stopping anyone from getting a DSLR, say a A230? For that price u can buy a DSLR, but that DSLR wud not have the advantage of small size & portability like the NEX5. So there's definitely a market for it & its not niche.

If u r using Sony DSLR & has invested lots of lenses & accessories, wud u get a Nikon D5000 or Canon 550D DSLR sys juz becos its cheaper than a customised NEX5 at $1500? It makes more sense to stick with a NEX5 thats customised to take advantage of the accessories & also lenses. In the DSLR territory its the same, wud u want to get another brand juz becos this brand has a cheaper model than the brand u r using? Jump ship, yes, but not for people who wants to continue using their arsenal built over the years.

Clean room assembling of cameras. That might be true for factory. My question to everyone out there is: Have u been inside the service center of any brand? Is it a clean room environment when they service equipment? I have been to a few in S'pore, can't say the same for the rest in the world. They r not clean room environment, juz aircon & people r not wearing any space suit, & that doesn't spell doom for the equipment & lenses being serviced there.

If the argument is made with a far fetch argument of "Who wants to customise a cam that cost $10k when the base model is $1k?" well, 1st of all, the makers controls what u can customised so it wudn't be over the hill. 2nd, if anyone wants to pay $5k juz to skin LV all over their NEX5 from LV boutique, thats their decision not mine or yours.

And yes, i do know how a DSLR works, & if u r not from research dept experimenting & developing new DSLR, i guess coming from u that the customising innards being impossible is moot.

The IR mod is only a removal of the Anti-aliasing filter and/or adding a IR filter in its place. They do not re-solder or add or remove any other parts.

And it's done at a risk of damaging the components totally. Which is why its normally done by the adventurous few and/or on older models of cameras.

What you advocate will only be available to the SUPER rich and bored.

It'll never materialise for the common masses.

And it's done at a risk of damaging the components totally. Which is why its normally done by the adventurous few and/or on older models of cameras.

What you advocate will only be available to the SUPER rich and bored.

It'll never materialise for the common masses.

WOW!! The RED is so tempting... :sweat::sweat::bsmilie:

I'm talking about the circuitry inside the DSLR, not about the mod itself. U'll see connectors & 1 or 2 daughter board inside as well, plus the parts r modular. The sensor is housed in an assembly unit module. Let say Nikon charge u $200 to add buffer to the D5000 (~1.3k), is that reserved for the rich? Another $60 for view finder that has bigger mag factor & more MF friendly. Prices like this is very reasonable & u still dun pay the price of a D300s. Why not? U can say its dumb to spend that money becos he/she cud buy a Canon 50D with better build. But for someone who doesn't want the weight of 50D, wants a tiltable/swivel screen, can do video, likes Nikon or has some Nikon lenses already, that becomes a good option.

Talking about customising being niche & expensive, lets look at another one we see daily. Cars.

From the agent direct u can already customise a few aspect. Colour of the car, leather upholstery seats, the colour of leather, audio sys enhancement, rims, IR film on glass to block heat, Bluetooth, AV entertainment, GPS, headlights LED or normal, security alarm sys, etc. These range from few hundreds to several thousands. Thats what customising is all about. People willing to spend on things they want/desire. Of cos there exist some hi end customising for the rich & niche, but i'm talking about mainstream direct from makers. :devil:

(ps. Btw, the pics were taken with a Lumix FX38 P&S, i'm pls with the clarity & sharpness )

)

The IR mod is only a removal of the Anti-aliasing filter and/or adding a IR filter in its place. They do not re-solder or add or remove any other parts.

And it's done at a risk of damaging the components totally. Which is why its normally done by the adventurous few and/or on older models of cameras.

What you advocate will only be available to the SUPER rich and bored.

It'll never materialise for the common masses.

I'm talking about the circuitry inside the DSLR, not about the mod itself. U'll see connectors & 1 or 2 daughter board inside as well, plus the parts r modular. The sensor is housed in an assembly unit module. Let say Nikon charge u $200 to add buffer to the D5000 (~1.3k), is that reserved for the rich? Another $60 for view finder that has bigger mag factor & more MF friendly. Prices like this is very reasonable & u still dun pay the price of a D300s. Why not? U can say its dumb to spend that money becos he/she cud buy a Canon 50D with better build. But for someone who doesn't want the weight of 50D, wants a tiltable/swivel screen, can do video, likes Nikon or has some Nikon lenses already, that becomes a good option.

Talking about customising being niche & expensive, lets look at another one we see daily. Cars.

From the agent direct u can already customise a few aspect. Colour of the car, leather upholstery seats, the colour of leather, audio sys enhancement, rims, IR film on glass to block heat, Bluetooth, AV entertainment, GPS, headlights LED or normal, security alarm sys, etc. These range from few hundreds to several thousands. Thats what customising is all about. People willing to spend on things they want/desire. Of cos there exist some hi end customising for the rich & niche, but i'm talking about mainstream direct from makers. :devil:

(ps. Btw, the pics were taken with a Lumix FX38 P&S, i'm pls with the clarity & sharpness

Last edited:

WOW!! The RED is so tempting... :sweat::sweat::bsmilie:

I'm talking about the circuitry inside the DSLR, not about the mod itself. U'll see connectors & 1 or 2 daughter board inside as well, plus the parts r modular. The sensor is housed in an assembly unit module. Let say Nikon charge u $200 to add buffer to the D5000 (~1.3k), is that reserved for the rich? Another $60 for view finder that has bigger mag factor & more MF friendly. Prices like this is very reasonable & u still dun pay the price of a D300s. Why not? U can say its dumb to spend that money becos he/she cud buy a Canon 50D with better build. But for someone who doesn't want the weight of 50D, wants a tiltable/swivel screen, can do video, likes Nikon or has some Nikon lenses already, that becomes a good option.

Talking about customising being niche & expensive, lets look at another one we see daily. Cars.

From the agent direct u can already customise a few aspect. Colour of the car, leather upholstery seats, the colour of leather, audio sys enhancement, rims, IR film on glass to block heat, Bluetooth, AV entertainment, GPS, headlights LED or normal, security alarm sys, etc. These range from few hundreds to several thousands. Thats what customising is all about. People willing to spend on things they want/desire. Of cos there exist some hi end customising for the rich & niche, but i'm talking about mainstream direct from makers. :devil:

(ps. Btw, the pics were taken with a Lumix FX38 P&S, i'm pls with the clarity & sharpness)

You really don't see the picture do you.

Who's gonna man the booths to modify the camera for you? Who's gonna dedicate a clean room location for such mods and requests?

How much is it going to cost for the camera makers to head in this direction when they are saving so much cost in just mass producing the same cameras for everyone?

Its juz plugging daughter boards into the main board, what kind of precision u need? I reckon a light industry place for "assembly line" is enuf. If it can be custumise like this, those parts r readily available, bout 10days waiting?

Are you sure the sensors, the AF sensors etc.. are not assembled with precision?

If the AF sensor and CMOS/CCD are not assemble with precision wrt to each other, all the pictures will be OOF.

You really don't see the picture do you.

Who's gonna man the booths to modify the camera for you? Who's gonna dedicate a clean room location for such mods and requests?

How much is it going to cost for the camera makers to head in this direction when they are saving so much cost in just mass producing the same cameras for everyone?

The only pic i see is a bright & beautiful one. HAHAHAHA!!!

Did i say anything about having booth? Now i see what u see :sweat: Clean room? We went thru that already.

Limsgp said:Are you sure the sensors, the AF sensors etc.. are not assembled with precision?

If the AF sensor and CMOS/CCD are not assemble with precision wrt to each other, all the pictures will be OOF.

Dun qote me out of context le. That statement is made wrt to pluging in a daughter board module. Did i say no need calibration for sensor? Pls refer to post no. 7 again

Last edited:

For eg, a Sony NEX or Oly m43

1) Colour : The retail shops sells only black, online store has options for white, red & navy blue.

Possible.

2) Buffer : Base model can shoot 10 RAW in buffer, u can opt to upgrade the RAM to go 16 RAW

Potentially expensive, as the RAM is soldered on as opposed to slotted in like on laptops (i.e. more precision work -> more manpower costs)

3) Video : Base model shoots 720p. Options can be Off, 1080i or 1080p

Most probably expensive. Unlike PCs/laptops where the CPU is kind of "standard" (standard slot size/firmware) and from limited manufacturers (Dell, Acer, Toshiba, Apple etc. ALL get their chips from either Intel or AMD), sensors for cameras in general tends to be more varied to cater for the different zoom range (P&S) and different algorithms (noise reduction etc. etc.). Hence a lot more R&D costs will be needed to develop "compatible" sensors with different capabilities which can be "swapped" onto the mainboard as per user's specifications.

4) Adapter mount : Base uses it new mount but need adaptor to be mounted for use of DSLR lenses. Option is to have a mount permanently screwed into the body so users dun need to buy 2 sets of lenses to enjoy the sys.

Possbile, but what's the point? If you go for a mirrorless system over a DSLR, isn't the whole advantage the size and weight? Why would anyone want to permanently limit themselves to the bigger and heavier DSLR lenses?

5) Flash : Base model has GN 7 at ISO 100, option can boost it to 12 with a longer tube

Potentially expensive, both in R&D and actual development costs. The current trend is "the smaller the better". To accommodate a longer tube, space has to be set aside in the camera for that during IC design phase, not to mention designing for the power a longer tube will consume. As it is impractical to manufacture different boards with different circuitry (unless their market demand estimation is so accurate, and even then there's extra costs of having different blueprints for different IC prints), those opting for weaker flash will still have to bear the costs of the more expensive circuitry designed for the stronger flash. And then consumers will start to complain "why is it so expensive"...

6) Sensor : Base model is 14MP CMOS. Option can choose 14MP Exmor or 16MP Super CCDII

Again, this goes back to point 3 about video so I won't repeat myself here.

7) LCD screen : Base model is normal LCD 230k. Option can choose 420k AMOLED, or 920k touch screen Super AMOLED

Yet another potentially expensive option. I doubt camera manufacturers design their own LCD - it's probably ordered from third party manufacturers. So different screens may have different connectors or different power consumption requirements (unless LCD manufacturers standardized it), and thus we go back to the costs of having to design different circuit boards to accommodate these variations. Plus ordering a single type of LCD in bulk is probably cheaper than ordering some of these, some of that...

While I can continue with points 8-10, I think you should get the idea by now that the costs of all these customisations will likely drive the cameras out of the average joe's budget range, which IS the market segment that the mirrorless systems are targeted at. (i.e. those wanting more than a P&S but don't want the size and price of a dslr, although there are dslr enthusiasts who use them too).

Next, for the connectors you showed in the pictures, I think those are more of ease of taking apart the camera (for servicing purposes). E.g. connector for LCD + back buttons to mainboard; connector for sensor board to mainboard. The stuff you suggested customizing (flash, sensor etc.) are soldered on directly.

It's a nice concept, and I wouldn't say it is impossible to make true. However for things like this to happen, it would take a concerted effort from all the camera makers to set some standards. Imagine if Dell, Acer, Toshiba, Apple etc. are all using different CPUs (i.e. not limited to Intel or AMD, and there is no standards among the different CPU types) and have their own non-standard RAM configurations (i.e. No standards like SDRAM, DDR, DDR2, DDR3 etc.). Would customization be possible? I highly doubt so.

6) Sensor : Base model is 14MP CMOS. Option can choose 14MP Exmor or 16MP Super CCDII

Dun qote me out of context le. That statement is made wrt to pluging in a daughter board module. Did i say no need calibration for sensor? Pls refer to post no. 7 again

Well. sensor is 1 of your upgrade option..

The question is this ...

How much incremental revenue or market share is this "customization" effort going to bring to the manufacturer ? Manufacturer think in "millions" of dollars in incremental revenue.

What do they have to alter in the manufacturing process to adapt to this customization ? Line changes, new processes, new testing methodology ? All these take time and money, which eats into current operations.

In terms of handling "special orders", the manufacturer will have to set up a special unit just to handle orders. Production and logistics department will have to set up or dedicate resources to liaise with these new orders. Most likely current resources are maxed out, so the introduction of any deviation to normal operations will necessitate new resource allocation and unless the numbers in terms of incremental revenue or market share can justify, it would be difficult to get approval to divert resources to set up such a unit.

What do the "local retailers" have to do in terms of preparedness to support the "customized" product ? Training, spare parts ? what if local cannot support, does it get shipped back to HQ and if it does, how does HQ handle ? Special department ? Money to set up again ...

These are just some issues that big manufacturers deal with .. multi miillion dollar business, to justify changes / deviations .. revenue changes numbers must be big too

my 2 cents worth

How much incremental revenue or market share is this "customization" effort going to bring to the manufacturer ? Manufacturer think in "millions" of dollars in incremental revenue.

What do they have to alter in the manufacturing process to adapt to this customization ? Line changes, new processes, new testing methodology ? All these take time and money, which eats into current operations.

In terms of handling "special orders", the manufacturer will have to set up a special unit just to handle orders. Production and logistics department will have to set up or dedicate resources to liaise with these new orders. Most likely current resources are maxed out, so the introduction of any deviation to normal operations will necessitate new resource allocation and unless the numbers in terms of incremental revenue or market share can justify, it would be difficult to get approval to divert resources to set up such a unit.

What do the "local retailers" have to do in terms of preparedness to support the "customized" product ? Training, spare parts ? what if local cannot support, does it get shipped back to HQ and if it does, how does HQ handle ? Special department ? Money to set up again ...

These are just some issues that big manufacturers deal with .. multi miillion dollar business, to justify changes / deviations .. revenue changes numbers must be big too

my 2 cents worth

Last edited:

Yes & post no. 7 says:Limsgp said:Well. sensor is 1 of your upgrade option..

Maybe changing sensor will require some calibration but thats juz a scope away, no need clean room le.

arctos said:1) Color : Possible.

2) Buffer : Potentially expensive, as the RAM is soldered on as opposed to slotted in like on laptops (i.e. more precision work -> more manpower costs)

3) Video : Most probably expensive. Unlike PCs/laptops where the CPU is kind of "standard" (standard slot size/firmware) and from limited manufacturers (Dell, Acer, Toshiba, Apple etc.

4) Adapter mount : Possbile, but what's the point? If you go for a mirrorless system over a DSLR, isn't the whole advantage the size and weight? Why would anyone want to permanently limit themselves to the bigger and heavier DSLR lenses?

5) Flash : Potentially expensive, both in R&D and actual development costs. The current trend is "the smaller the better". To accommodate a longer tube, space has to be set aside in the camera for that during IC design phase, not to mention designing for the power a longer tube will consume. As it is impractical to manufacture different boards with different circuitry (unless their market demand estimation is so accurate, and even then there's extra costs of having different blueprints for different IC prints)

6) Sensor : Again, this goes back to point 3 about video so I won't repeat myself here.

7) LCD screen : Yet another potentially expensive option. I doubt camera manufacturers design their own LCD - it's probably ordered from third party manufacturers. So different screens may have different connectors or different power consumption requirements (unless LCD manufacturers standardized it), and thus we go back to the costs of having to design different circuit boards to accommodate these variations. Plus ordering a single type of LCD in bulk is probably cheaper than ordering some of these, some of that...

It's a nice concept, and I wouldn't say it is impossible to make true. However for things like this to happen, it would take a concerted effort from all the camera makers to set some standards. Imagine if Dell, Acer, Toshiba, Apple etc. are all using different CPUs (i.e. not limited to Intel or AMD, and there is no standards among the different CPU types) and have their own non-standard RAM configurations (i.e. No standards like SDRAM, DDR, DDR2, DDR3 etc.).

Thank u. Those r very good pointers

i also go thru point by point:

2) Buffer : Yes the ram r soldered, but they will be on a daughter card. This fits into the main board easily. Same for PC rams, they r soldered but in slot form for easy installation of computers. So i dun really see it as a hindrance to the cost & implementation

3) Video : The recent news is a hack was done to the GH1 & GF1 where it can enable 1080i shooting from default 720p. This cud be a firmware enabling process (like PCs), so not really that costly i reckon.

4) Adaptor : There r people who juz want to use their existing lens, for cost or quality reasons. As to why wud anyone wants that, its a very personal choice. I'll be one of those kind actually, if i buy a PEN, i will use my 14-54 on it instead of the kit lens

5) Flash : The flash module is "pre-fab" daughter board. The tube itself can be slotted in instead of the soldered type. If u look at the pic with flash, u'll see there's still some space for the capacitor to "grow longer" & the tube as well to accommodate the extra GN. Besides from GN7 to 11, its not that big power jump

6) Sensor : When my E1 sensor was damaged, Oly quoted my ~$640 to get it replaced. I think this is still a "down to earth" pricing. Exp to some but hey, there r people out there spending $65k on car audio sys in their Mitsubishi instead of buying a BMW

7) LCD screen : This i agree but u never know what co. can source.

Again, these r juz some of my thots, makers get to decide ultimately what options to give customers.

zero o, u have made some very valid points as well. Thank u

I can see why so many r against this concept. To me, if it works for other industries, it can work with the camera industry as well. U need to develop it to make it work. Currently i see many "objections" were derived from fitting in a new concept in an old model. I rem when apple 1st announced the iPhone plan, many were skeptical/neg about it. Reason being those people r fitting apple's phone into existing winmo & nokia model. But apple has other plans & develop the phone based on their plans, & not try to fit into others' old shoe.

Keep the pointers coming guys, i really appreciate it :lovegrin:

Yes & post no. 7 says:

It's just an example. My point is, a camera is not like a computer.

In a computer, only electrical signal flow around the system. And as long as there is good electrical contact between the different components and the charge can flow freely, there is not much concern to the exact positions of each component.

But a camera is different. It's not just electrical signal flowing around. the light path needs to be controlled carefully. That's why I say precision is needed.

The act of opening, reassembling the camera might affect/disturb the alignments of the sensor/shutter/mirror etc..

Even if you're just changing electronic components, precision is needed so as not to disturb/affect the other parts of the camera system.

So, it has to be done by the factory or special outlets with the right skilled operator and precision equipment.

2) Buffer : Yes the ram r soldered, but they will be on a daughter card. This fits into the main board easily. Same for PC rams, they r soldered but in slot form for easy installation of computers. So i dun really see it as a hindrance to the cost & implementation

PC: RAM chips are soldered onto RAM sticks which are then slotted onto the motherboard. So for your idea to take hold, somebody's got to come up with standards for RAM sticks in camera. And this ignores the issue of added bulk (think GPU onboard RAM vs PC RAM - the most variation they give is 256MB vs 512MB rather than your 512MB/1GB/2GB/3GB etc. etc.). You don't buy a Kingston 1GB and stick it onto your GPU do you? ;p

3) Video : The recent news is a hack was done to the GH1 & GF1 where it can enable 1080i shooting from default 720p. This cud be a firmware enabling process (like PCs), so not really that costly i reckon.

But who's going to pay the poor programmer in-charge of developing the firmware? And the technicians for loading the correct firmware you chose in your customization? And that's provided the sensor is capable of the feature in the first place (meaning that those opting for the lesser option would be short-changed into paying for more that they can't use).

4) Adaptor : There r people who juz want to use their existing lens, for cost or quality reasons. As to why wud anyone wants that, its a very personal choice. I'll be one of those kind actually, if i buy a PEN, i will use my 14-54 on it instead of the kit lens

And how many such people are there, and how much are they willing to pay for this feature to justify the increase in costs for an additional manufacturing/assembly line?

5) Flash : The flash module is "pre-fab" daughter board. The tube itself can be slotted in instead of the soldered type. If u look at the pic with flash, u'll see there's still some space for the capacitor to "grow longer" & the tube as well to accommodate the extra GN. Besides from GN7 to 11, its not that big power jump

So if my remote control uses AAA batteries, can I slot in AA batteries to give it more power? Different sizes, different design. It's not just a matter of slotting in. And while you and I may feel that the power difference is minute, an IC design may tell you differently. Again, it all boils down to cost.

I can see why so many r against this concept. To me, if it works for other industries, it can work with the camera industry as well. U need to develop it to make it work. Currently i see many "objections" were derived from fitting in a new concept in an old model. I rem when apple 1st announced the iPhone plan, many were skeptical/neg about it. Reason being those people r fitting apple's phone into existing winmo & nokia model. But apple has other plans & develop the phone based on their plans, & not try to fit into others' old shoe.

Erm... I might get mobbed by Apple fans for this, but the iPhone popularity has largely to do with the fact that it's APPLE, period. Non-Apple fans have quite a fair bit of grouses about the iPhone after getting it. The iPhone is not revolutionary or anything, but it is seen as "hip" and "cool" (and I'll admit that it's more stable than WinMo phones - coz they freaking control everything you can or cannot put in starting from the developer's code).

It isn't impossible for customization, but like I said, it would involve a heavily concerted effort by the camera manufacturers to push for standards so that costs can be kept down by avoiding too many variations.

PC: RAM chips are soldered onto RAM sticks which are then slotted onto the motherboard. So for your idea to take hold, somebody's got to come up with standards for RAM sticks in camera. And this ignores the issue of added bulk (think GPU onboard RAM vs PC RAM - the most variation they give is 256MB vs 512MB rather than your 512MB/1GB/2GB/3GB etc. etc.). You don't buy a Kingston 1GB and stick it onto your GPU do you? ;p

3) Video : The recent news is a hack was done to the GH1 & GF1 where it can enable 1080i shooting from default 720p. This cud be a firmware enabling process (like PCs), so not really that costly i reckon.

But who's going to pay the poor programmer in-charge of developing the firmware? And the technicians for loading the correct firmware you chose in your customization? And that's provided the sensor is capable of the feature in the first place (meaning that those opting for the lesser option would be short-changed into paying for more that they can't use).

4) Adaptor : There r people who juz want to use their existing lens, for cost or quality reasons. As to why wud anyone wants that, its a very personal choice. I'll be one of those kind actually, if i buy a PEN, i will use my 14-54 on it instead of the kit lens

And how many such people are there, and how much are they willing to pay for this feature to justify the increase in costs for an additional manufacturing/assembly line?

5) Flash : The flash module is "pre-fab" daughter board. The tube itself can be slotted in instead of the soldered type. If u look at the pic with flash, u'll see there's still some space for the capacitor to "grow longer" & the tube as well to accommodate the extra GN. Besides from GN7 to 11, its not that big power jump

So if my remote control uses AAA batteries, can I slot in AA batteries to give it more power? Different sizes, different design. It's not just a matter of slotting in. And while you and I may feel that the power difference is minute, an IC design may tell you differently. Again, it all boils down to cost.

I can see why so many r against this concept. To me, if it works for other industries, it can work with the camera industry as well. U need to develop it to make it work. Currently i see many "objections" were derived from fitting in a new concept in an old model. I rem when apple 1st announced the iPhone plan, many were skeptical/neg about it. Reason being those people r fitting apple's phone into existing winmo & nokia model. But apple has other plans & develop the phone based on their plans, & not try to fit into others' old shoe.

Erm... I might get mobbed by Apple fans for this, but the iPhone popularity has largely to do with the fact that it's APPLE, period. Non-Apple fans have quite a fair bit of grouses about the iPhone after getting it. The iPhone is not revolutionary or anything, but it is seen as "hip" and "cool" (and I'll admit that it's more stable than WinMo phones - coz they freaking control everything you can or cannot put in starting from the developer's code).

It isn't impossible for customization, but like I said, it would involve a heavily concerted effort by the camera manufacturers to push for standards so that costs can be kept down by avoiding too many variations.

Last edited:

It's just an example. My point is, a camera is not like a computer.

In a computer, only electrical signal flow around the system. And as long as there is good electrical contact between the different components and the charge can flow freely, there is not much concern to the exact positions of each component.

But a camera is different. It's not just electrical signal flowing around. the light path needs to be controlled carefully. That's why I say precision is needed.

The act of opening, reassembling the camera might affect/disturb the alignments of the sensor/shutter/mirror etc..

Even if you're just changing electronic components, precision is needed so as not to disturb/affect the other parts of the camera system.

So, it has to be done by the factory or special outlets with the right skilled operator and precision equipment.

Understand ur point.

Dun misunderstood this new concept. All those customised parts r not solely for a particular model only. They can be found & used in other models as well, may it be lower end or higher end.

Similar threads

- Replies

- 0

- Views

- 46

- Replies

- 0

- Views

- 133

- Replies

- 0

- Views

- 137

- Replies

- 3

- Views

- 306

- Replies

- 0

- Views

- 119