hi all,

just sharing what I have done to replace the aged cells for my NP-E3 battery pack.

CAUTION :

please note that I am not responsible for any camera damages or battery damages should you tries to copy what I have done here. I am also not working or advertising for Sanyo.

The following steps or pictures is purely for viewing and knowledge purpose. Basic electronic skills and knowhow should be imparted in the person handling this rework.

I have purchased a 3rd party battery pack ( NP-E3 , 1650mAh ) for my 1D camera. I start using from June 2007 and now, the pack is no longer able to hold charge already. After charging, the battery pack capacity will drop drastically after about 100 shots.

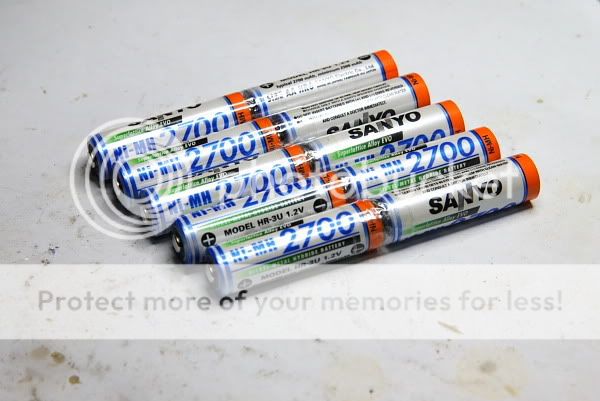

Due to technology improve, the capacity available commercially is now 2700mAh. I purchased 10 pcs of the SANYO 2700mAh NiMH cells for the replacement.

#1. 10x Sanyo 2700mAh NiMH cells for replacement

#2. I remove the battery catch lever

#3. I remove the TOP cover using a screw driver

#4. Remove the bottom casing also

just sharing what I have done to replace the aged cells for my NP-E3 battery pack.

CAUTION :

please note that I am not responsible for any camera damages or battery damages should you tries to copy what I have done here. I am also not working or advertising for Sanyo.

The following steps or pictures is purely for viewing and knowledge purpose. Basic electronic skills and knowhow should be imparted in the person handling this rework.

I have purchased a 3rd party battery pack ( NP-E3 , 1650mAh ) for my 1D camera. I start using from June 2007 and now, the pack is no longer able to hold charge already. After charging, the battery pack capacity will drop drastically after about 100 shots.

Due to technology improve, the capacity available commercially is now 2700mAh. I purchased 10 pcs of the SANYO 2700mAh NiMH cells for the replacement.

#1. 10x Sanyo 2700mAh NiMH cells for replacement

#2. I remove the battery catch lever

#3. I remove the TOP cover using a screw driver

#4. Remove the bottom casing also